3D printing is becoming pretty popular, and these days you can get your hands on virtually anything from 3D-printed shoes to AR-15’s. There still isn’t, however, a lot of 3D-printed outdoor gear; it’s just not something you see very often and to be honest, there isn’t a huge demand for it. That didn’t stop a team of design students and a doctoral candidate from the ETH Design Lab, at the Zurich University of the Arts in Switzerland, from designing a 3D printed campstove prototype – the PeakBoil Camp Stove.

At first glance, the PeakBoil does not look anything like a regular campstove, but it promises to boil water faster than your regular campstove (even faster than a Jetboil?) and do away with the most annoying part of camp cooking: having your flame blown out by the wind.

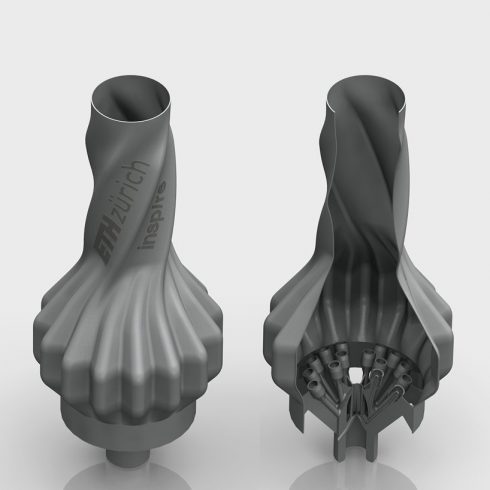

Instead of the traditional flame-underneath-the-pot design of regular campstoves, the PeakBoil uses a stainless steel, 3D-printed kettle, “shaped like a Bundt tin,” with a gas burner enclosed and protected from strong winds. The stainless steel has been created by melting thin layers of metal together, in a process similar to melting plastic, allowing it to be much thinner and more precisely-crafted into unique shapes than casted metal.

The design uses a unique rippled-wall shape, which increases the contact area between the flame and the stove for more efficient heat usage. The thinness of the stainless-steel walls also means it transfers heat more effectively. Inside the burner are Venturi nozzles, which decrease pressure for increased airflow and an even-more efficient flame. Less fuel, faster boiling.

At the moment, this is just a prototype, and the design team in Switzerland is dedicated to fine-tuning it into an exact, precise tool. They already gave it a test run on Santis, the highest mounting in the Alpstein massif, and it held up to the high winds well. When it’s finished, they’re looking for someone to manufacture and distribute it.

Until then, we’ll just have to boil our water the old-fashioned way.